QT8-15 China automatic cement hollow brick block making machine price

Compared with traditional brick machine, automatic cement brick making machine can produce cement bricks without burning. It adopts the advanced technology, which the characteristics of compact structure, simple operation, low failure rate, stable performance and high productivity.

1.Main Technical Specifications

| Dimension of host machine | 3800×2200×2750mm |

| Pallet size | 1050 ×900 ×30mm |

| Weight of host machine | 10.5T |

| Vibration force | 70-100KN |

| Installed capacity | 45kw |

| Molding cycle | 15-20s |

| Intensity of pressure | 15-20mpa |

| Vibration frequency | 2800-4500 |

2.Fully automatic concrete block machine production line included

|

1. cement silo |

2. 6m screw conveyor |

|

3. cement and water scale |

4. batching machine |

|

5.concrete mixer |

6. material hopper |

|

7.hydraulic station |

8.material conveyor belt |

|

9.pallet feeder |

10.block receiver |

|

11.PLC station |

12.concrete brick machine |

|

13.stacker |

14.forklift |

3.Theoretical capacity

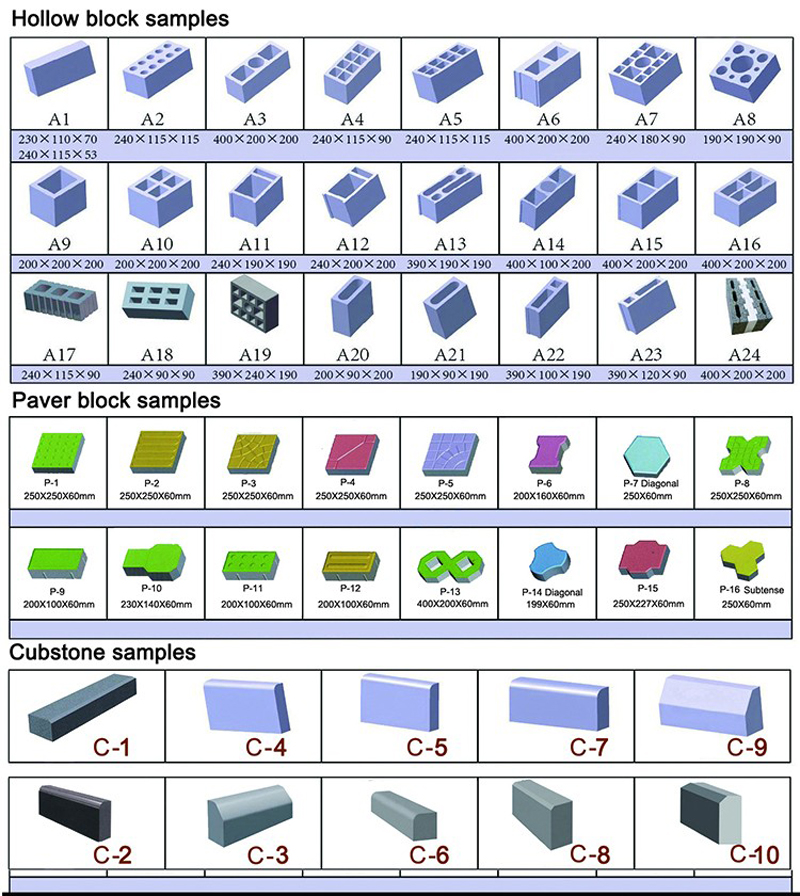

| Item | Picture | Specification(L×W×H) |

QTY/Mould

(pcs)

|

|

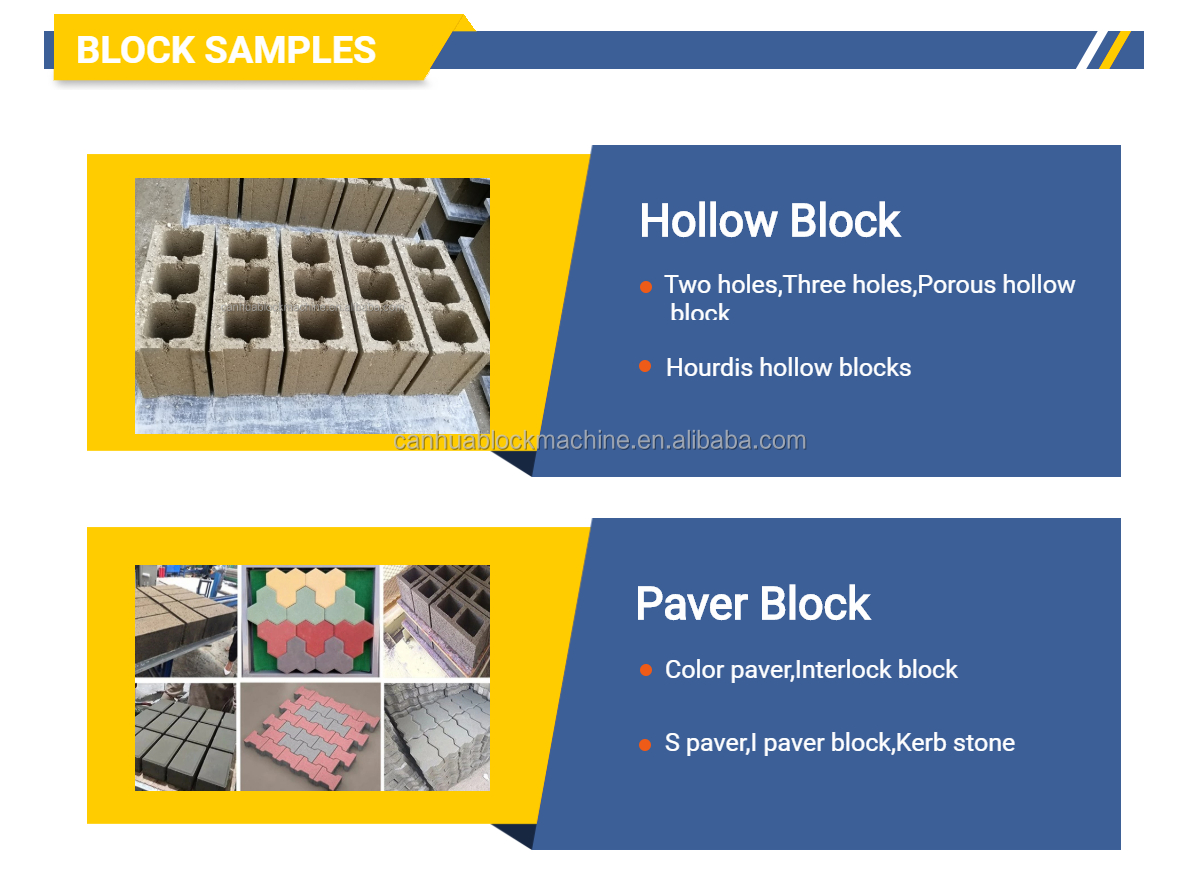

| Concrete hollow block |

|

400×250×200mm | 6 | 8640 |

| 400×200×200mm | 8 | 11520-15360 | ||

| Porous hollow block |

|

240×115×90mm | 21 | 30240-40320 |

| Solid block |

|

240×115×53mm | 45 | 64800-86400 |

| Paver |

|

200×100×60mm | 28 | 40320 |

|

200×163×60mm | 20 | 28800 |

Other details about the hollow block machine you may interested

1).Supply ability of our factory: 50 sets per momth

2).Machine color: according to your requirement

3).Block mould: One set free for you,others according different size different price.

4).Generator needed: 100kw.

5).Working area needed: about 3000-4000m2.

6).Delivery port: Qingdao,China.

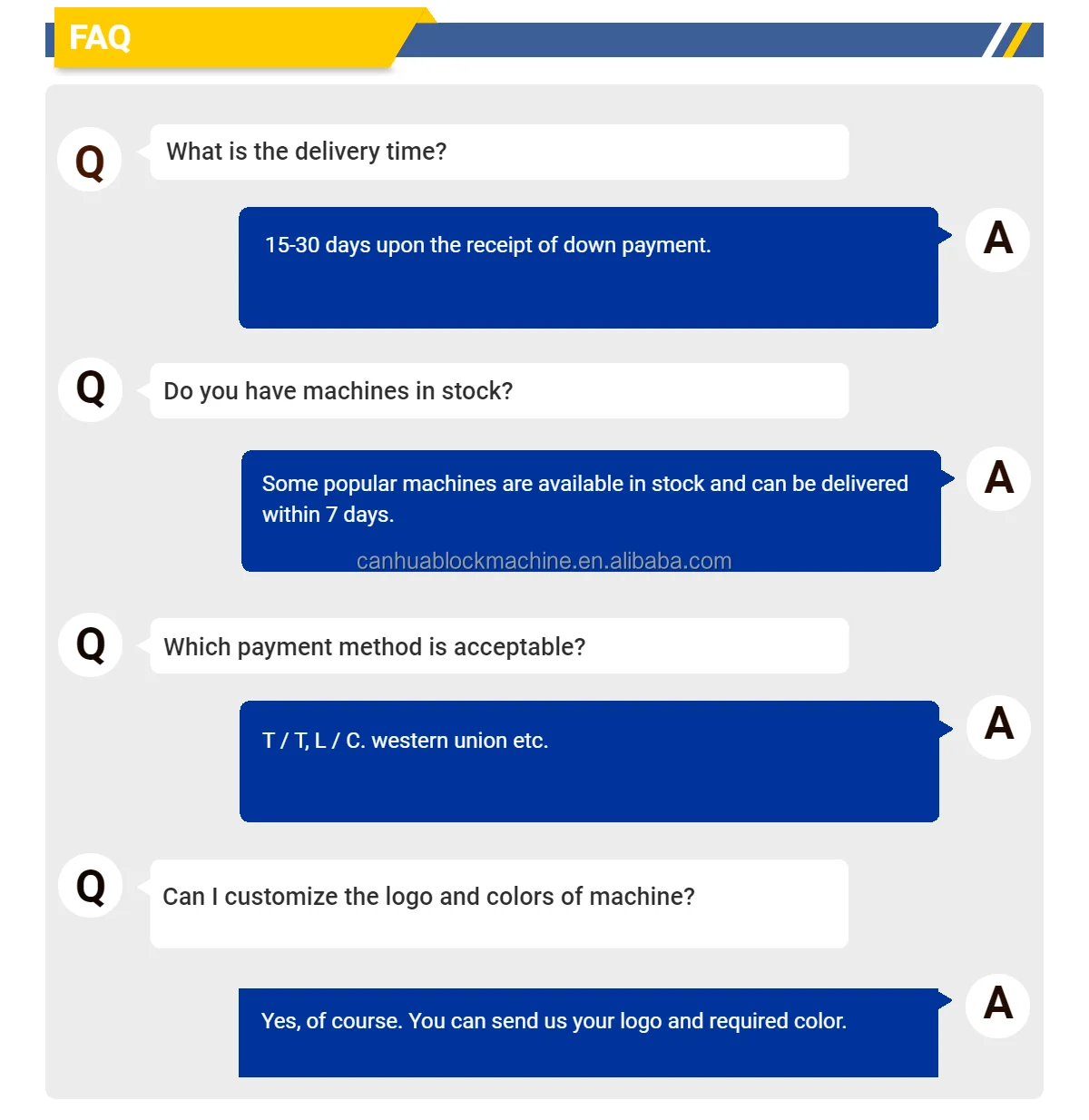

7).Delivery date:1 set,about need 15-20 days;more than 1 set,need to be negotiate.

8).Payment: You can choose the payment convenience by your side.

9).We are concrete hollow block making machine factory directly, not trading company, and we can arrange engineer to your side install the machine and training workers at the first time,you no need worry about the after sale service.

1. The whole concrete interlocking block making machine production line equipment is mainly the full container sea shipping,

2. Block making machine for sale equipment finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire cement brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift.

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the hollow block making machine.