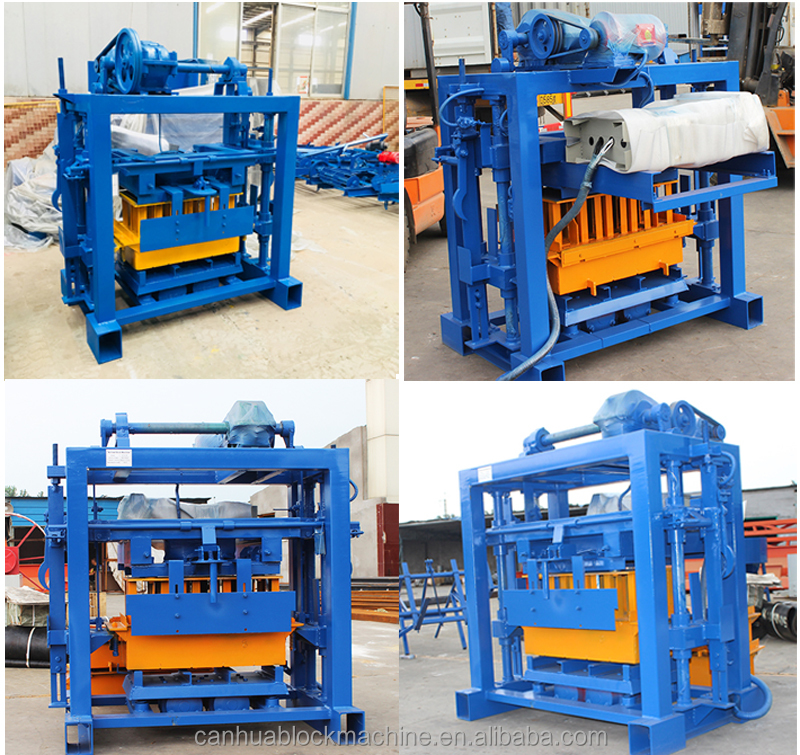

QT40-2 small manual hollow concrete block making machine

QT40-2 Main Advantages

1) Low cost and high reliability.

2) Durable and cost-effective, electric cabinet control .

3) Solid and Strong Machine Body

4) Perfect after-sale service, spare part and tools free for customer

5) Produce stronger and quality bricks. The block is of good quality, large density and high strength. The hollow block making machine used on the push mode, and automatic scraper, convenient and flexible operation, and its performance can be comparable with the large-scale equipment.

|

Main Technical Parameters |

|||

|

Dimension |

1350x1460x1800mm |

Host machine power |

8.8 KW |

|

Vibration force |

30KN |

Weight of the machine |

about 1.8T |

|

Size of pallet |

850x450x25/30mm |

Mixer Model |

JQ350 |

Brief Introduction for QT40-2 Total Set

(1). Manual Operation, Easy Maintenance

(2). Produce sizes of hollow block, solid brick, hourdis, paver and curbstone by changing molds.

(3).Wall block: 2500-5000 Pcs/ 8 H

Paver: 5500-10000 Pcs/ 8 H

(4). Block plant investment amount range: 3200-5000 USD

(5). Suitable for Small-scale Block Factory and New Starters

(6). Professional manufacturer: Produce any sizes and shapes of molds as you want

(7). Workers Number: 4-5 Workers

One workers to load material into Mixer

One Workers to operate block machine, add pallet into block machine

One workers to load material into block machine

One to Two workers to carry fresh blocks to curing size

(8). Factory Area : 600-1000M2

(9).Pallet Number: For QT40-2 block making machine line: 600 pallet

Sancidalo Machinery Factory supply bamboo pallet, fiber (GMT) pallet and PVC pallet. We recommend you the bamboo pallet.

Production Capacity

QT40-2 manual cement concrete brick moulding machine can produce sizes of hollow block, solid brick, pavers, hourds and curbstone by changing molds. the production capacity is as followed:

|

Item |

Block |

Production capacity |

Photo |

|

1 |

Hollow/Solid block 400-200-200mm |

4 pcs/mold |

|

|

2 |

Hollow/Solid block 400-150-200mm |

5 pcs/mold |

|

|

3 |

Hollow/Solid block 400-100-200mm |

7 pcs/mold |

|

|

4 |

Houdi block 450-120-200mm |

6 pcs/mold |

|

|

5 |

S shape paver 225-112.5-60mm |

12 pcs/mold |

|

|

6 |

I shape paver 200-160-60mm |

8 pcs/mold |

|

|

7 |

Holland paver 200-100-60mm |

12 pcs/mold |

|

Main Parts Advantages

1) Control box: Use control box to ensure the machine operation safety. Famous brand electric parts and button ,emergency stop.

2) Machine main motor: The motor use china famous brand, also can use ABB or Siemens motor according your request.

3) Block mould: Adopts linear cutting technology and fire cutting machine to make sure accuracy size ,Mould is changeable ,the manual cement block making machine can produce different bricks to meet with client's requirements. high temperature heat treated and carburization ,longer service life.

FAQ

(1).What is your terms of packing?

A: Large fly ash brick making machine need to load into container transport, small machines need to LCL suitable for sea transport.

(2).How about your delivery time?

A: Generally,we will shipped in 20 days after payment.

(3).Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings. We can build the moulds and fixtures.

(4).Do you provide block sample?

A: You can visit our factory, here has so many blocks samples show in factory.

(5).Have you test all your block machinery before delivery?

A: Yes, we have 100% test the machine before delivery.

(6).How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit; Also we respect every of our customer as our friend and we sincerely do business and make friends with them, no matter where they come from.