QT4-24 china low cost widely used concrete hollow block making machine

This machine is one small type hollow block making machine, can make different size hollow block, solid bricks, pavers, S blocks and so on.

We accept your customized hollow block mold size, also can supply you brick samples for your reference.

1.Main Technical Parameters

| Dimension of host machine | 2060x1880x2240mm |

|

| Pallet size | 850x550x25mm | |

| Weight of host machine | 1.8T | |

| Vibration force | 35.5KN | |

| Power of host machine | 13.35kw | |

| Molding cycle | 24-26s | |

| Intensity of pressure | 15Mpa | |

| Mixer model | JD350 |

2.QT4-24 cement hollow brick machine worksite details and material information

1). Area: Workshop area: 80-100m2, all factory area 3000m2, the bigger, the better.

2). Workers : five to eight.

3). Ratio of raw material: cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

4). hollow block weight:

(400*200*200) :17KG,(190*140*190):13.5KG,(390*90*190):10KG

5). Raw material consumption per day:50-70T

6). Water consumption per day:3%-5% of raw material Weight.

|

Concrete block machine line area needed |

|||

|

Workshop |

60 m2 |

||

|

Office |

50m2 |

||

|

Total area |

about 2000m2 |

||

|

Worker arrangement |

|||

|

operate |

1 |

Material loader |

1 |

|

Drive trolley |

1 |

Total |

3 |

Theoretical capacity of QT4-24 concrete hollow block machine

|

Item |

Block |

Production capacity |

Photo |

|

1 |

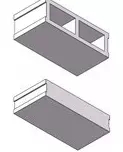

Hollow/Solid block 400-200-200mm |

4 pcs/mold |

|

|

2 |

Hollow/Solid block 400-150-200mm |

5 pcs/mold |

|

|

3 |

Hollow/Solid block 400-100-200mm |

7 pcs/mold |

|

|

4 |

Hourdis block 450-120-200mm |

6 pcs/mold |

|

|

5 |

S shape paver 225-112.5-60mm |

12 pcs/mold |

|

|

6 |

I shape paver 200-160-60mm |

8 pcs/mold |

|

|

7 |

Holland paver 200-100-60mm |

12 pcs/mold |

|

1)Superior vibratory effect: Simultaneous vibration. the hollow blocks produced are of good quality, large density and high strength.

2)High quality block machine body: Best steel Q235B and special welding techniques (CO2 gas protective welding ) make the block machine strong and of high resistance to vibration.

3)High Quality Mould: All brick making machine moulds are can use more than 120,000 times.

4)This machine is much easy operated, and very low investment, you can make many difference blocks and bricks by changing mold easily.

|

Brick MoldAdopt precise line cutting and carburizing treatment technology prolong the mold life and increase the precision of the brick mold, so the brick molds have better performance |

Vibration System

1.Adopt vibration molding technology and equipped with three vibrators to assure better quality,larger density and higher strength of the blocks. |

|

|

Electric Cabinet Control SystemAdvanced electric control system and clearly screen display make the operation more convenient. Electrical components are made in famous factories, which can make a long time service. |